Liquid Volume Dispenser

Introducing new innovative product by SAVIK Enterprises – “Liquid Volume Dispenser” This fully automatic unit measures the volume of liquid flowing through a pipe and closes Solenoid valve when desired volume of liquid is dispensed. Here initially user needs to set the required volume of liquid using keypad. Once the volume is set, the unit opens solenoid valve and starts measuring volume of liquid. Once the set volume is reached, it closes solenoid valve again.

Features & Benefits:

Metal Enclosure, Easy installation, low maintenance

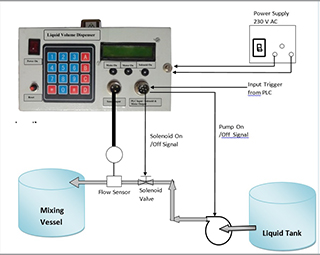

Can be easily operated by PLC, by giving simple trigger pulse

Separate Potential free contacts for connection with Motor and Solenoid Valve

Supports Single Phase

LED indications for Motor ON, Solenoid On and Mains On.

The unit can be used for water flow from 1L/ Min to 30 L/ Min with default flow sensor. But we also provide customized unit as per customer’s requirement. (Can be customized for different fluids and flow rates)

Set Volume and Actual dispensed volume are continuously displayed on LDC.

User settable “Set Volume”

This can be best low cost substitution for volume measurement meter / flow meters.

Application:

Chemical Industries, Process plants, Food Industries where accurate volume of liquid is required and process is repeated.

Schematic of Liquid Volume Dispenser

How to use?

Steps to start:

1. After doing appropriate connections, power on the unit.

2. Now enter the required volume of liquid and press ‘#’ key using keypad.

3. Now the unit will wait for a trigger from PLC. (If user doesn’t want to use PLC, This trigger can be given manually to start the process.)

4. After getting trigger, relay contact for motor is operated to start motor. After few seconds, relay contact for solenoid valve is operated to open solenoid valve and start dispensing liquid.

5. During process, Set volume and measured / dispensed volume is continuously displayed on LCD.

6. When measured volume is equal to set volume, Motor is stopped and Solenoid valve is closed immediately.

7. Now again unit will wait for trigger to start the process (Either manually or From PLC).

8. Press “Reset” switch to change the “Set Volume”.